Pelletisation and torrefaction

BIOS has being active in national and international engineering and R&D projects in the field of densified biomass fuels (i.e. pellets and briquettes) since 2000. The working field of BIOS covers the whole range of production and utilisation of pellets and torrefied biomass and includes planning and optimisation of pellet production plants, analyses, characterisation and evaluation of raw materials and pellets as well as CFD-aided development and optimisation of pellet combustion and gasification technologies. The aforementioned working fields are also applied in the field of torrefied biomass – with a special focus on development and optimisation of torrefaction reactors and plants as well as on the development of combustion and gasification technologies for torrefied biomass.

In all working fields mentioned BIOS is active in research, technological development and planning and is a competent and experienced partner for its customers.

BIOS also published two reference books related to pellets:

„Herstellung und energetische Nutzung von Pellets“

„The Pellet Handbook – The production and thermal utilisation of biomass pellets“

Conventional softwood pellets

pellets from torrefied beech

Sectors

BIOS performs engineering and R&D work for the following clients / customers:

- Producers of pellets and torrefied biomass

- Manufacturers of pellet furnaces and gasifiers

- Manufacturers of torrefaction reactors

- Plant operators and utilities

- Municipalities, public authorities

- R&D institutions

Scope and services

The scope and services of BIOS cover the engineering and R&D work itself as well as possible administration and funding related issues.

Planning and optimisation of pellet production plants

- All planning activities relevant for the realisation of a pellet production plant can be covered by BIOS.

- Optimisation of raw material pre-treatment for subsequent pelletisation

Raw material pre-treatment and milling must thoroughly be adapted to the densification properties of the raw material used (e.g. selection of the milling technology, raw material mixtures). - Optimisation of heat supply for raw material drying

Especially in case of using wet raw materials special attention must be put on the energy supply, as raw material drying is one of the main cost factors in pellet production. - Energy master plans

They aim at a most efficient utilisation of available heat sources including heat recovery from the production process itself. Energy master plans are integral part of planning activities for new plants but are also of relevance for the optimisation of existing pellet production plants. - Planning for pellet production plants including energy supply

If both pellet production plant and heat supplying plant should together be newly erected BIOS offers the planning of the whole plant including plants providing the heat needed for raw material drying, which could be heat-only plants or biomass combined heat and power plants. - Wood chips and log wood as raw materials for pelletisation

These raw materials gain increasing importance in pellet production (due to the increasing shortage of the currently most important raw materials, i.e. wood shavings and sawdust, and due to funding requirements – e.g. the request of using pellets exclusively produced from forest wood (no sawmill by-products allowed) to gain ÖMAG feed-in tariffs in Austria) and require careful planning to keep production costs low. - Raw material characterisation

A sound characterisation of raw materials before planning and erection of a pellet production plant is offered to evaluate its applicability for the pelletisation process and the pellet quality to be expected. BIOS has respective analytical possibilities and is active in several R&D projects regarding raw material and pellet characterisation.

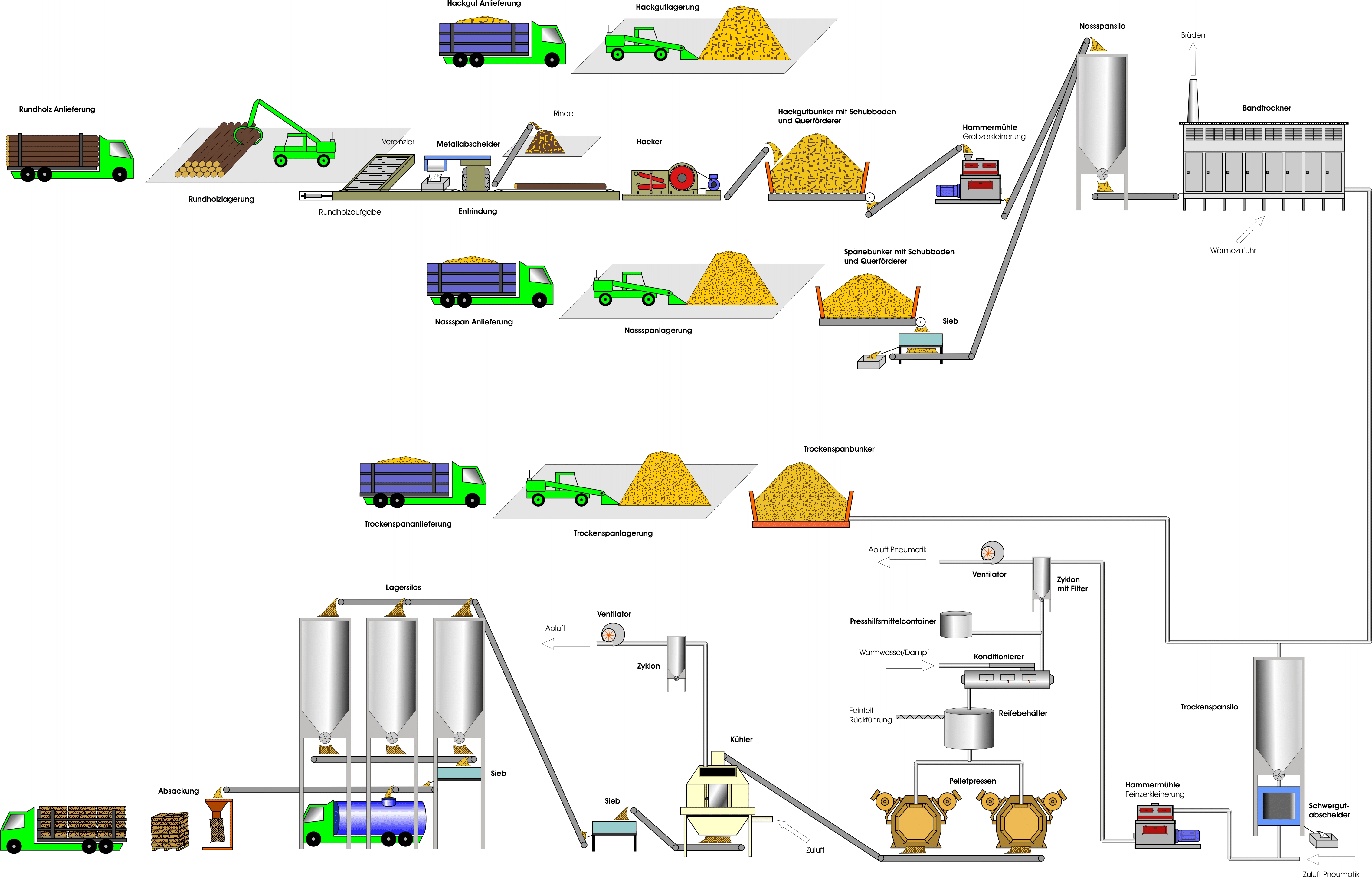

Scheme of a pellet production plant

Analyses and characterisation of pellets

- Analyses of pellets

Based on the corresponding EN and ISO wood pellet standards the following parameters can be analysed: dimensions, particle and bulk density, abrasion, gross calorific value, moisture content, ash content, concentrations of the elements N, S, Cl, Cu, Zn, As, Cr, Pb, Cd and Hg.

If required, the parameters ash melting behaviour, K, Na, Ca, Mg, Si, Fe, Al, Mn und P as well as C and H are offered.

In addition, the determination of the particle size distribution of raw materials and pellets based on a photometric method can be offered. - Characterisation of pellets

BIOS offers a detailed evaluation of the pellets analysed with regard to their combustion behaviour (especially relevant for pellets from alternative raw materials). - Lab-scale reactor tests with pellets

Lab-scale reactor tests aim at the determination of the pyrolysis, gasification and burnout behaviour as well as the accompanied release of organic and inorganic compounds from the fuel in a fixed-bed. The mass loss over time in the rector, the development of the concentrations of the single flue gas components above the fuel bed as well as the fuel and flue gas temperatures are recorded and taken as a basis to evaluate the fuel. In addition, an optical evaluation and analysis of the residues allows a pre-evaluation of the ash melting behaviour.

Straw pellets before

Straw pellets after a lab-scale reactor test

CFD-aided development of pellet combustion and gasification technologies

- CFD simulations allow a significant reduction of development times and costs for test runs and they increase the reliability in plant development. Moreover, they contribute to an improved basic understanding of the processes taking place in combustion, gasification or pyrolysis reactors.

- BIOS supports all development and optimisation activities by CFD simulations and has a long lasting an in-depth expertise in the development and optimisation of pellet combustion and gasification technologies.

Respective developments and optimisations have already been performed for well-known pellet furnace and gasifier manufacturers, thereunder KWB, Viessmann, Windhager, Guntamatic, SL-Technik, ETA, Fröling, RIKA and Ploytechnik. - Pellet furnace and gasifier developments take place in all for Austria relevant size ranges:

Pellet stoves: up to about 10 kW

Pellet central heating furnaces: up to about 100 kW

Medium-sized pellet furnaces and gasifiers (e.g. for the application in micro-grids, micro-CHP systems or process heat supply): up to about 500 kW

Pellet combustion and gasification technologies in the range of 0.5 to 10 MW for biomass heating and biomass CHP plants as well as for generation of industrial process heat. - Example for a successful pellet furnace development

A new highly efficient low-emission wood chips and pellet hybrid furnace technology in the power range of 50-500 kW is being developed within a collaborative project with the company SL-Technik GmbH (see picture below). This newly developed plant reached a Guinness World Record for the most efficient hybrid biomass heating system (non-condensing) with a efficiency of 98% at nominal load operation.

Newly, in cooperation with BIOS developed wood chips and pellet hybrid furnace technology, which reached an efficiency related Guinness World Record (Source: SL-Technik GmbH)

Typical aims in the development and optimisation of pellet furnaces:

- Optimised efficiencies

- Low emissions (especially regarding PM, CO, OGC and NOx)

- High plant availabilities

- Pellet furnaces specially designed for “new” biomass fuels such as straw or miscanthus.

- Additivation of pellets and/or intelligent raw material blending to influence the ash melting behaviour as well as the particulate emissions positively.

Production and utilisation of torrefied biomass

- CFD-supported development, optimisation and planning of torrefaction reactors and plants

BIOS has simulations tools available which are able to describe biomass pyrolysis in detail. - Typical development targets are:

Optimisation of the yield of torrefied biomass

Optimisation of the energy efficiency and the product quality

Improvement of the compaction properties of torrefied biomass

Reduction of dust, soot and tar related problems in ducts for torrgas - Regarding utilisation of torrefied biomass BIOS offers the following:

Characterisation of the combustion and gasification behaviour of torrefied biomass in a specially designed lab-scale reactor

CFD-supported development of combustion and gasification technologies specially designed for torrefied biomass

Torrefied biomass

pellets from torrefied biomass