FlexiBioKWK

Development of a new fuel-flexible and highly efficient biomass CHP technology.

Link: Technology / Info: Biomass Gasification

In the course of this project, co-financed by the European Fund for Regional Development, BIOS BIOENERGIESYSTEME GmbH is developing a new biomass CHP technology. This technology should be characterized by high efficiencies, significantly improved fuel flexibility compared to existing concepts and improved economic efficiency.

Biochar for Industry

Development of a process to produce biochar of a quality that makes it suitable to be applied as a substitute for fossil carbon in metallurgical processes at competitive prices.

Link: Technology / Info: Biomass Pyrolysis

- As added-value products of the process besides biochar also green electricity and heat shall further reduce the CO2 emissions of the energy sector.

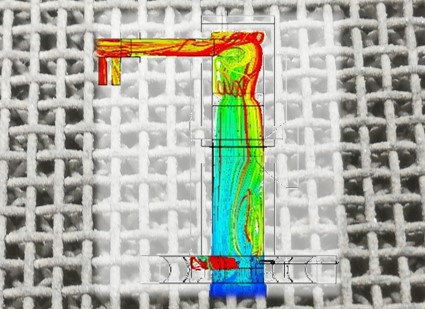

- CFD (Computational Fluid Dynamics) simulation based optimisation of the pyrolysis process and development of the pyrolysis gas upgrading for heat and power generation.

- Performance and evaluation of test runs at a prototype plant.

- Development of application concepts in the metallurgical industry.

AgroBioHeat

Promoting the penetration of agrobiomass heating solutions in European rural areas.

Link: www.agrobioheat.eu

Testing of small and medium-scale biomass boilers regarding their performance when utilising agro-biomass. Development of guidlines for combustion technologies for agro-biomass.

LowEmi-MicroStove

Development of a new low-cost low-emission micro-scale pellet stove with advanced process control.

Link: www.bio-micro-stove.eu

To make pellet stoves more competitive in the very low capacity range, the project aims at the development of an innovative, low-cost low-emission micro-scale (1 to 4 kW) pellet stove. Core elements of the new technology shall be a new pellet feeding system, a novel grate system, a CFD designed new combustion chamber with an improved insulation strategy and a control concept based on innovative sensors.

SOFC 5-60

High efficiency 5 kWel SOFC CHP development for flexible electricity and heat demand in buildings and small industries.

Link: Technology / Info: Electricity from Biomass / Fuel Cell (SOFC)

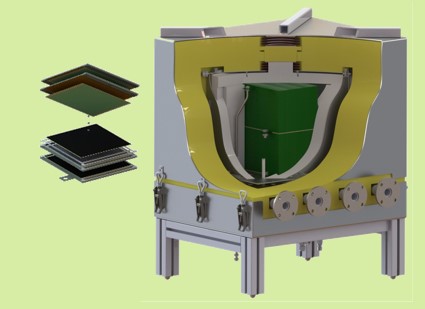

Development of a 5 kWel SOFC CHP (Solid Oxide Fuel Cell Combined Heat and Power) system for residential and non-residential applications.

Small-scale BM based CHP

Three different already existing concepts, which have already proven their suitability for biomass-based small/micro-CHP-applications have been further developed and techno-economically optimised in order to reach field test stage. These technologies are intended to cover the entire electric power range relevant for small-scale biomass combustion ranging from a few Watts up to 100 kW.

Wood Stoves 2020

New technologies resp. components for logwood stoves which shall lead to significant emission reductions and efficiency gains have been developed and tested. BIOS focused on the development and optimisation of a new next generation logwood stove technology which is equipped with an automatic control system and shows due to the utilisation of primary and secondary (integrated high temperature catalyst) emission reduction measures very low emissions as well as due to an integrated heat storage based on phase-change-material an efficiency of more than 90%.

HiEff-BioPower

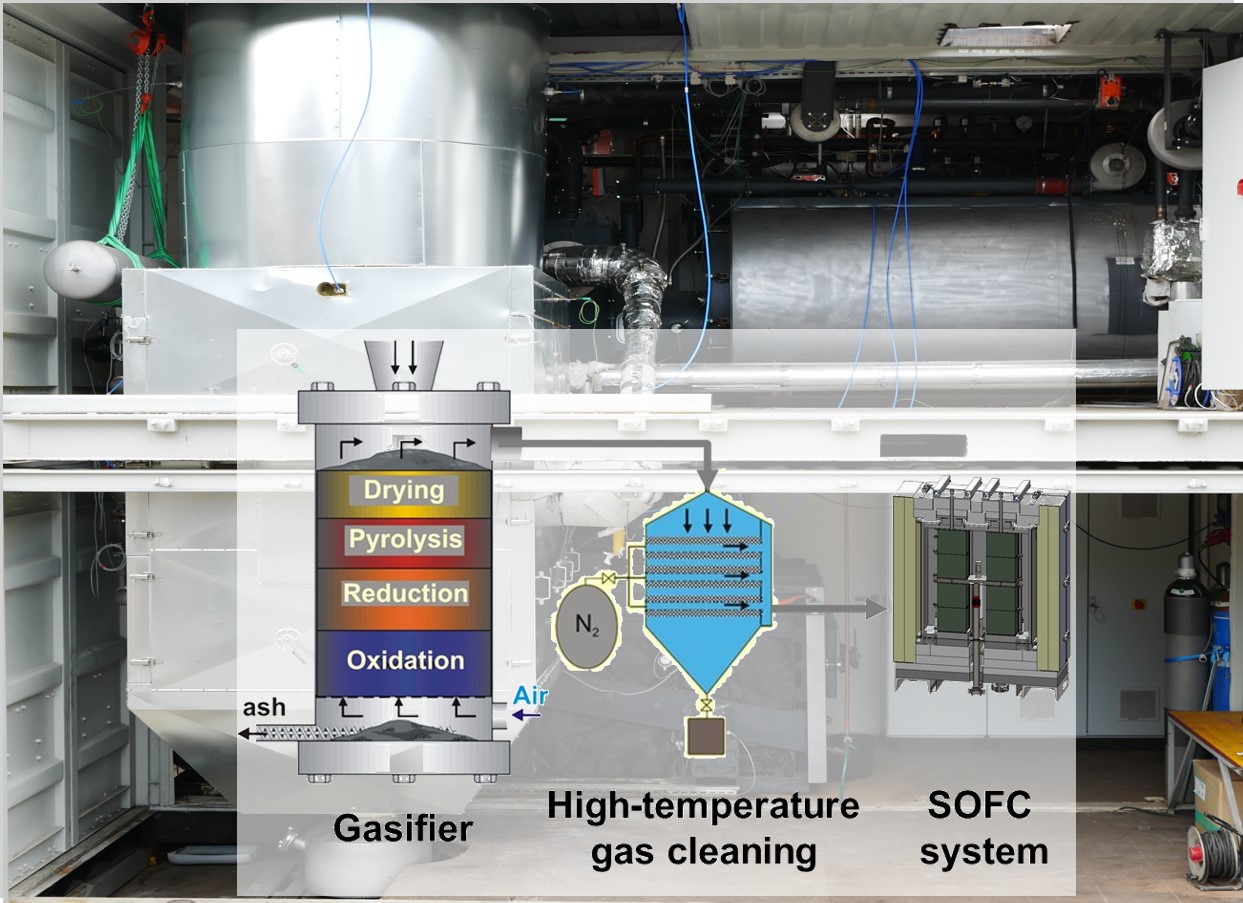

Development of a new highly efficient medium-scale CHP technology based on biomass gasification and SOFC.

Link: www.hieff-biopower.eu

Development of a highly efficient medium-scale (up to 10 MW) biomass CHP system based on a fixed-bed updraft gasifier, a compact gas cleaning unit and a SOFC system.

FlexiFuel-SOFC

Development of a new and fuel-flexible micro-scale biomass CHP system based on gasification and SOFC.

Link: www.flexifuelsofc.eu

Development of a new fuel-flexible biomass mirco-CHP system based on a fixed-bed updraft gasifier, a gas cleaning unit and a fuel cell system (SOFC). Capacity range: up to 150 kW fuel power..

FlexiFuel-CHX

Development of a fuel flexible and highly efficient ultra low emission residential-scale boiler with coupled heat recuperation based on flue gas condensation.

Link: www.flexifuelchx.eu

Development of a highly fuel-flexible and energy efficient small-scale biomass combustion technology based on a fixed-bed updraft gasifier connected with a gas burner, a boiler and a condensing heat exchanger.

BIOFLEX!

Clean and flexible use of new difficult biomass fuels in small to medium-scale combustion.

Link: www.bioflex-eranet.eu

The goal of the project is to enable the use of new “problematic” biomass fuels in small and medium-sized plants (<10 MW) at high efficiencies, low emissions and acceptable costs. This shall be achieved by the development of innovative fuel blending and additivation concepts as well as the further development of existing small and medium-scale combustion technologies. This involves laboratory reactor test runs with new difficult biomass fuels as well as the CFD-based development of fuel flexible technology concepts for fixed-bed combustion systems in the small (<500 kW) and medium-scale (up to 10 MW) as well as their subsequent test and stepwise optimisation and techno-economic analyses of the new technologies.

EnCat

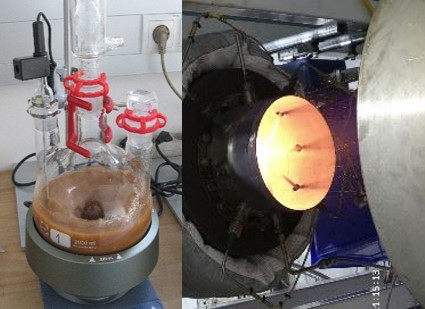

Enhanced catalytic fast pyrolysis of biomass for optimised production of high-quality biofuels.

Link: Technology / Info: Biomass Pyrolysis

Development of a novel concept based on fast pyrolyses for the prodcution of high quality boi-oil at high yields. Development of a biomass pre-treatment process by leaching the feedstock with the light (water-rich) fraction of the pyrolysis oil in order to partially remove ash forming elements. CFD simulation to develop a low-emission bio-oil combustion in gas turbines. BIOS also supports an economically meaningful development of the full-scale design of the new concept with accompanying techno-economic analyses.

Development of innovative processes for wood ash utilisation

National poject within the "Collective Research" program of the FFG (Austrian Research Promotion Agency) to evaluate and develop innovative processes for wood ash utilisation.

Link: Technology / Info: Ash utilisation

Main goals:

- Development of environmentally friendly and ready-to-use recycling processes for wood ash under consideration of already available results from national and international research projects.

- Evaluation of the complete process chain from combustion technology to treatment, logistics, transport and recycling of the ashes with the aim to close the mineral cycle while considering environmental and economic feasibility.

- Comprehensive evaluation and assessment of technological, agricultural as well as pedological aspects under consideration of the legal framework conditions and the economic feasibility in order to provide the basis for the implementation of the project results in legal guidelines, ordinances or laws.

- Focus on realistic and rather simple recycling processes.